The Centralized Torque Anchor (CTA) is designed to anchor the Tubing String and Progressive Cavity Pump (PCP) within the wellbore. The CTA consists of a unique anchor design, which incorporates 1 Floating Slip and 2 Rigid Slips that guarantee the Torque Anchor stays concentric within the wellbore casing. The CTA stops the right-hand rotation of the PC Pump, by providing “Superior Stabilization” of the PC Pump and eliminates tubing back-off.

Benefits:

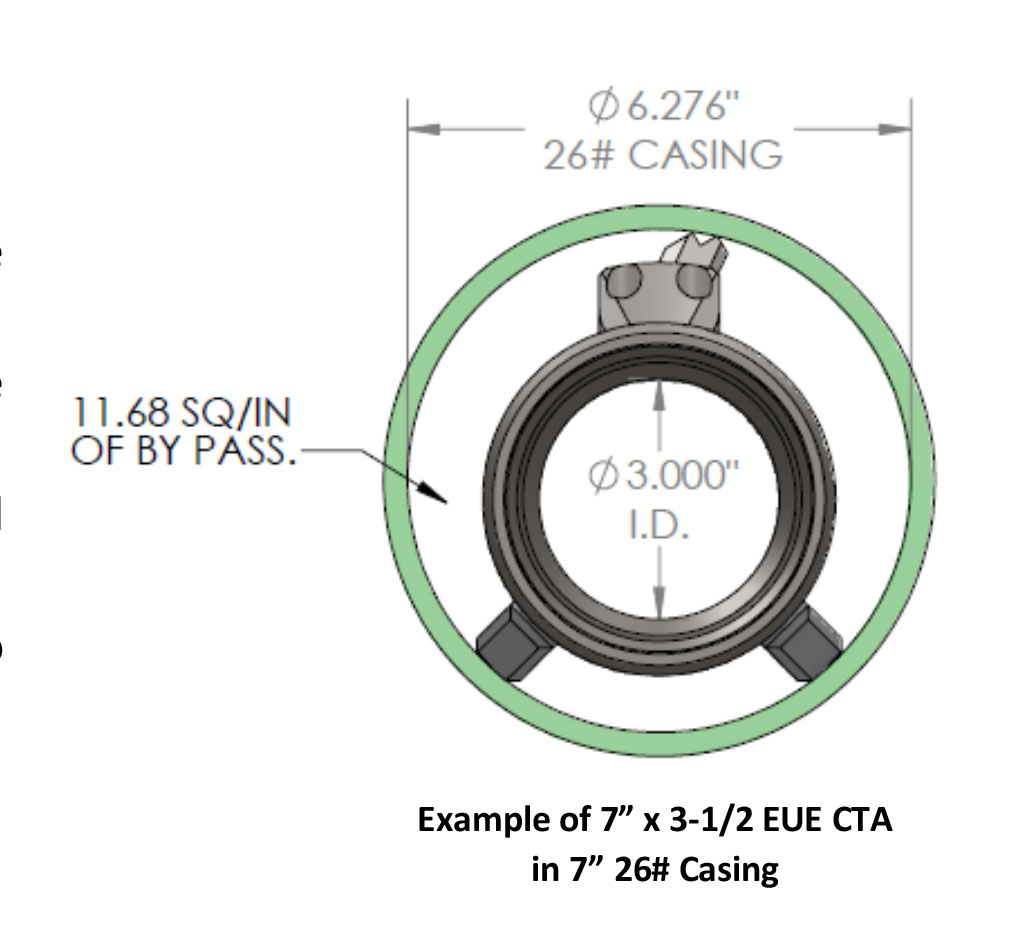

- Centralizing the Torque Anchor in the casing, allows for increased production, by lifting the Slotted Tag Bar and Gas Separator Intakes off the casing ID and out of the sand

- The open By-Pass area and centralized design, allows for greater annular space, for gas migration up the annulus, rather than inside the PC Pump. It also, allows for sand and coiled tubing to pass the CTA

- The CTA having a main body the same OD as the Stator leaves no place for sand to build up on the Tool. Result, the tool can be removed easily from sanded in wells

- The Rigid Slips provide a space to carry and protect the tech cable and/or diluent cables down well

- Solid Drive Pin and Floating Slip design for simple setting and straight pull-up release procedures

- Inconel springs for H2S and CO2 resistance

- Rebuilding procedure can be performed in the field.

Experience Matters

Operation:

- The Centralized Torque Anchor (CTA) is threaded onto the tubing string above or below the PC Pump.

- Run the tubing to the desired setting depth and land the tubing hanger. DO NOT tighten the lock screws.

- Pick up the tubing string so it is just off the hanger seat and apply right hand torque to the tubing to set the anchor.

- Set the tubing hanger back down and lock the hanger into place.

The CTA is released by straight pull-up from the wellbore.

Download PDF 267 kb (ALPRO CTA Brochure.pdf)