Progressing Cavity Pumps are a positive displacement pump perfectly suited to pumping highly viscous, abrasive substances. For this reason, the oil and gas industry has been using them to pump heavy oil since the 1980s, and today they have evolved to pumping medium and light crude oil, wells with high Gas-Oil-Ratios and de-watering natural gas and coal-bed methane wells.

Years of experience with different PC Pump manufacturers has taught us exactly what to look for when sourcing a PC Pump. We also sought to join forces with a company that holds similar corporate values and culture. Enter Artemis, an award winning, third-generation family owned company specializing in rubber and plastics for OEMs since 1975. Artemis is one of the leading manufacturers of rotors and stators for multiple industries around the world.

With its own, comprehensive elastomer compound development and production facilities, Artemis can produce compounds perfectly tailored for the pumping conditions and control every aspect of the quality, from the raw materials compounding through to the injection and curing. State of the art inspection techniques ensure only the highest quality product leaves their facility in accordance with their DIN EN ISO 9001:2000 rating.

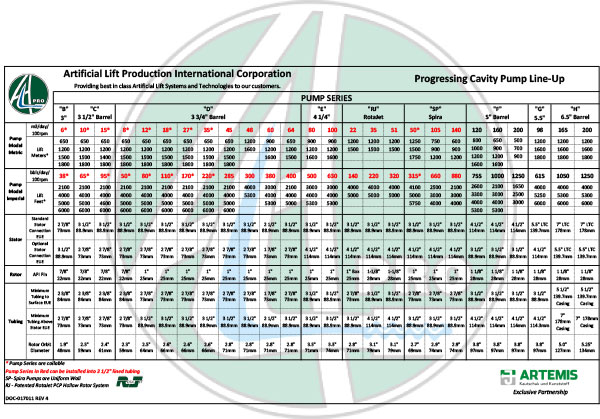

Pump Selection

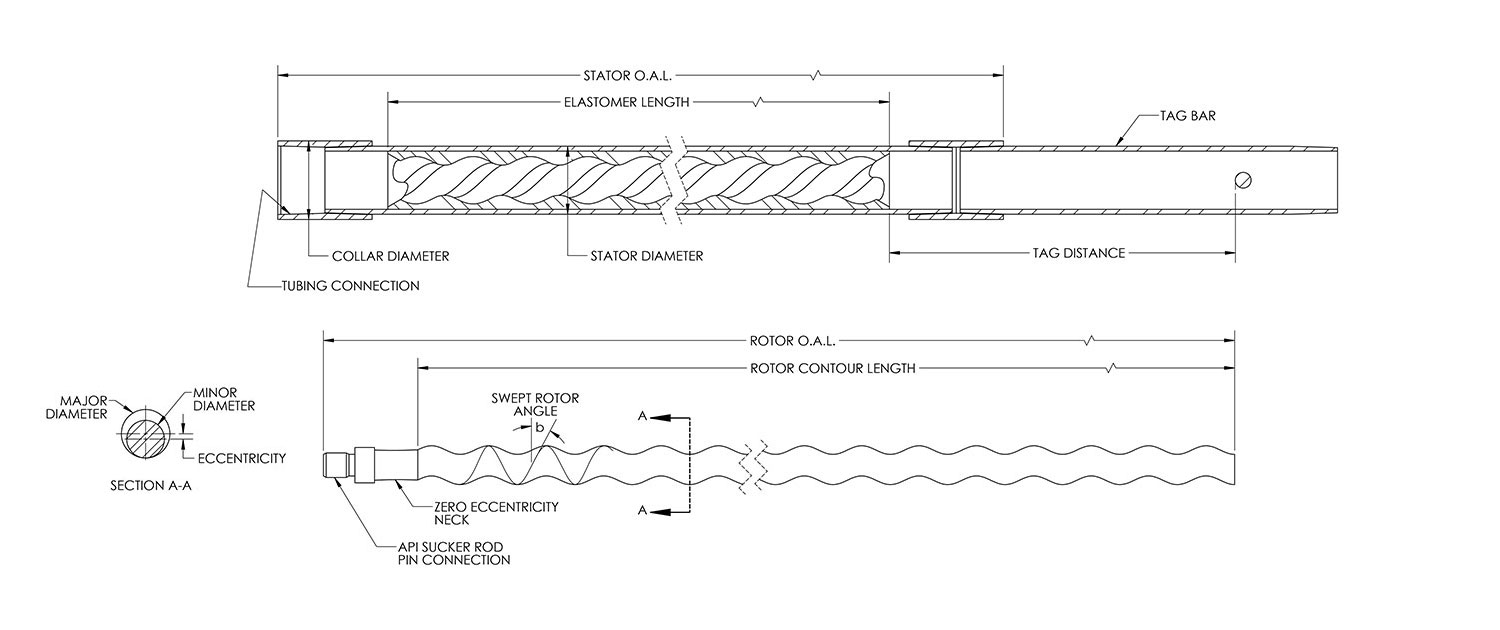

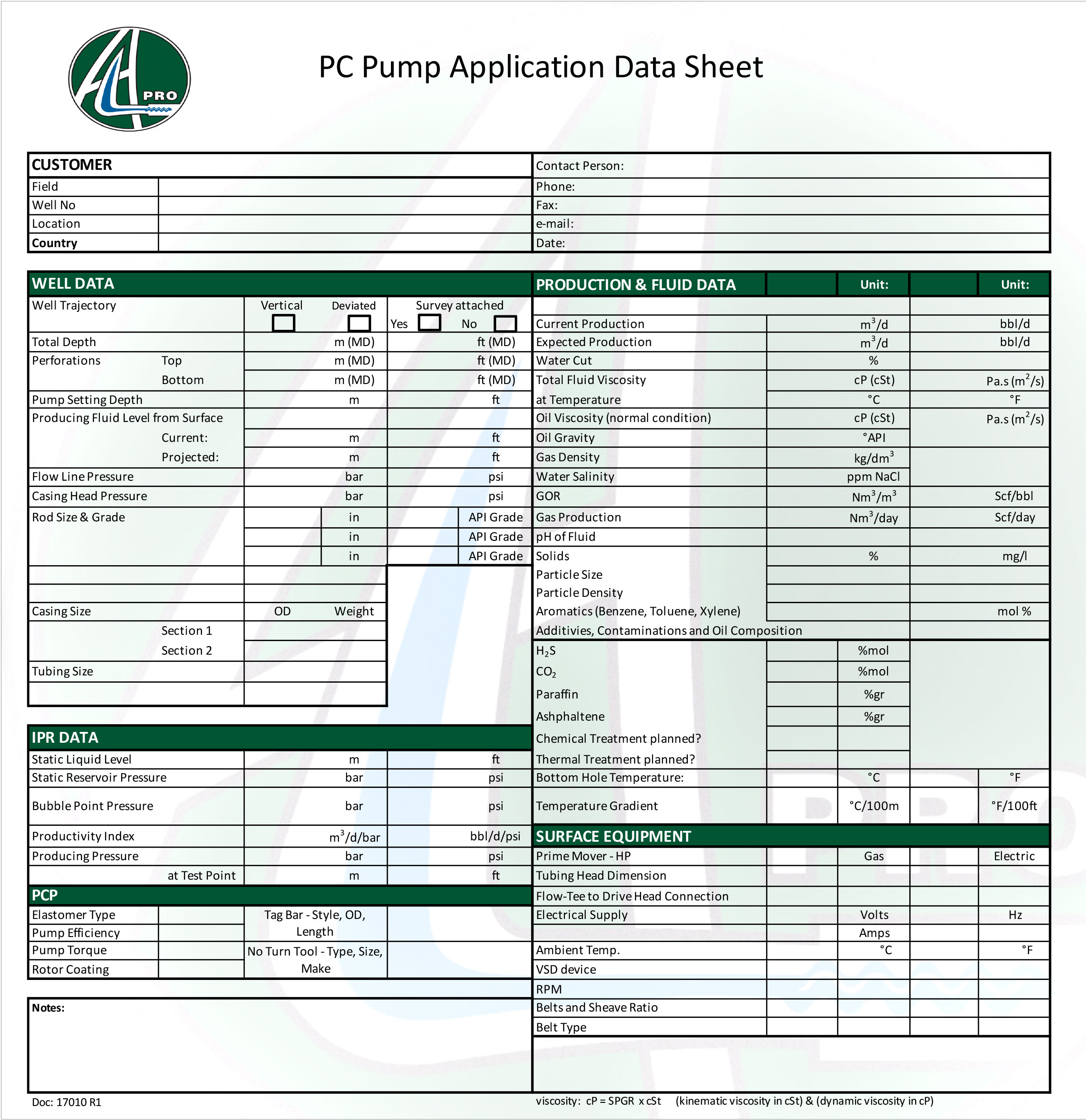

Although a PC Pump may seem like a simple machine, with only 2 parts and only 1 moving part, many factors contribute to a high quality long lasting pump. The design of the geometry, the interference fit between the rotor and stator, the uniformity of that fit from the intake to the discharge, the selection of the elastomer type and the reaction of the elastomer to the pumped fluid all have a profound effect on the run life of the pump. We consider all of these and more when we select a pump for your application.

Progressing Cavity Pump Line-Up (PDF download)